- Patchcords, pigtails, accessories

- Splitters, CWDM, DWDM

- Fiber optic service

How we produce splittersCellco Communications obtains the workstation which enables FBT modules production. Features: high flexibility, automatic control, easy operation control, high precision, built-in microscope, 3-D motion torch system, temperature monitor, dual wavelength monitoring, real time monitoring and many others.

In its simplest form, an FBT fiber coupler consists of two optical fibers in which the optical cladding has been fused together. Tapering this structure changes the core modes of the fibers, broadening the modal fields in the cladding. During the manufacturing process fibers are put one by one and than heated and pulled at the same time

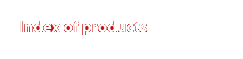

Example of proper 2x2 splitter manufacturing

Fiber can be extended under the condition of “semi-melt”, which is approached by proper temperature, torch height, size, gas flow, etc.

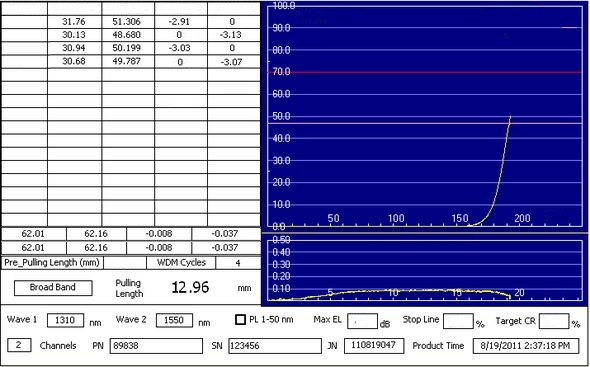

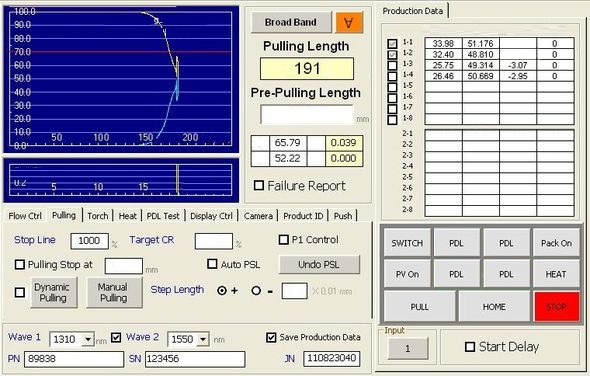

Example of 1x2 splitter manufacturing  Example of wideband test results

|

Catalogue of products

News: NEPTUN 3U 8X and 12X patchpanel NEPTUN 3U is a 19" patchpanel designed for easy organization of optical fibers, thanks to the use of modular cassettes. more >> |

||||||||||||||||||||||||||||||||